The problem is difficult to overstate.

The European Union alone generated approximately five million tons of electronic waste in 2022.

By 2030, global generation of e-waste isprojectedto increase to 74.7-82 million metric tons.

Meanwhile, the current state of electronic recycling is far from ideal.

Traditional recycling methods often involve manual dismantling, which is both costly and inefficient.

Moreover, many devices end up being shredded, a process that limits the potential for recovering valuable components.

It not only makes electronic recycling more effective but also could one day help manufacturers access valuable raw materials.

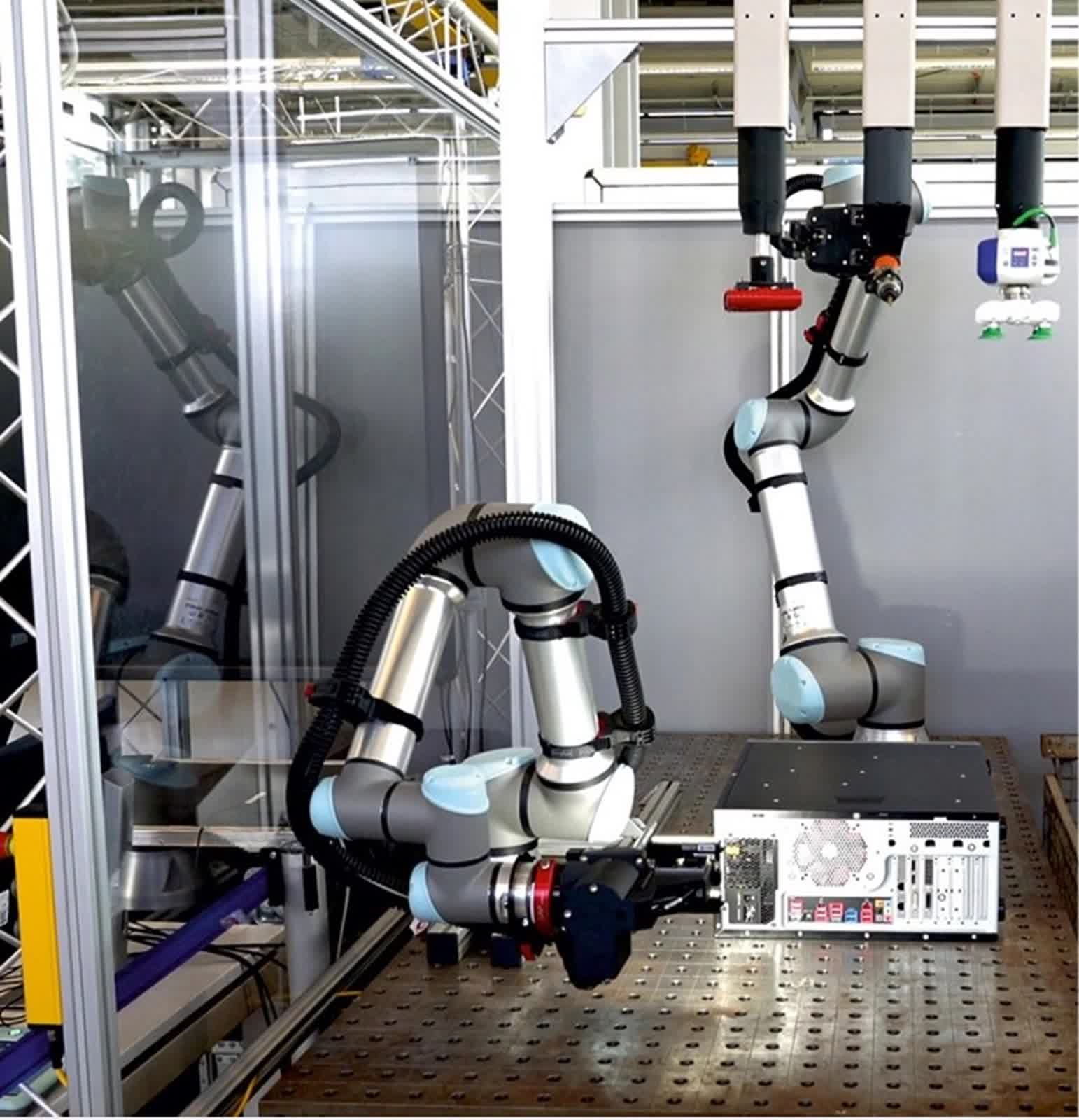

The iDEAR process begins with an identification and diagnosis phase.

It can identify, for instance, whether a screw is hidden or rusted, Saenz said.

A key innovation in the iDEAR project is the creation of a digital disassembly twin for each product.

Once the machine has been thoroughly analyzed, the system defines disassembly sequences using specialized software.