Imagine quickly printing a custom part for your bike or even medical equipment while on the go.

When the light hits the resin, it rapidly solidifies into a user-defined 3D shape.

This beam-steering capability is what enables the 3D printing magic.

The equipment features 160 optical antennas, all fitting within a US quarter-sized footprint.

However, the visible light wavelengths required for this technology initially posed a challenge.

Researchers at UT Austin addressed this by developing specialty resins optimized to cure under visible light exposure.

This innovation was the missing link needed to make chip-based 3D printing viable.

The potential applications are staggering from emergency repairs by first responders to printing medical devices on-demand.

MIT Professor Jelena Notarossaidthe system is completely rethinking what a 3D printer is.

Further details about the research can be found in a paperpublishedin the journal Nature.

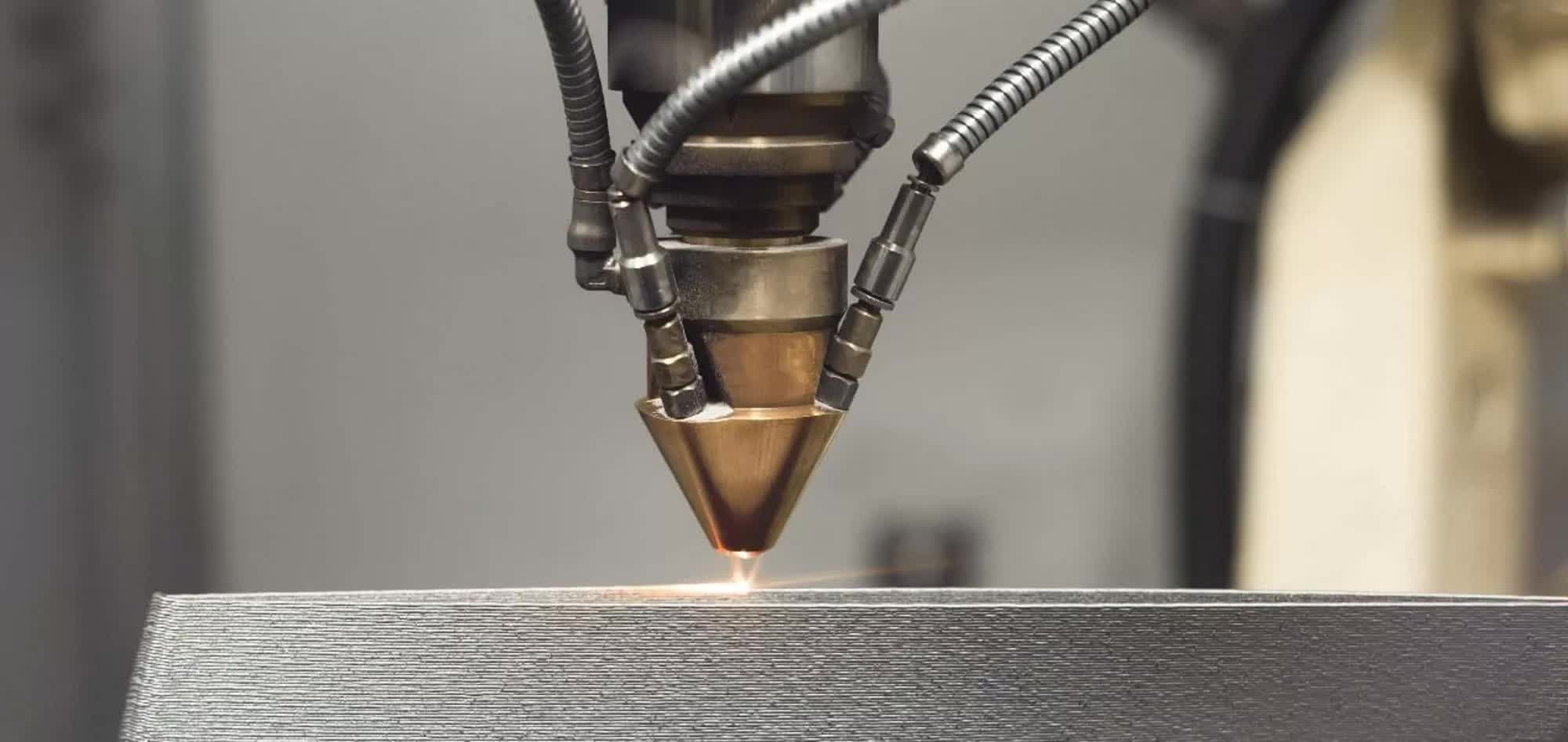

At the other end of the 3D printing spectrum is another rig unveiled in April.